![]()

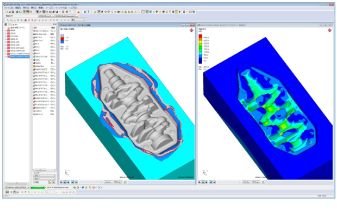

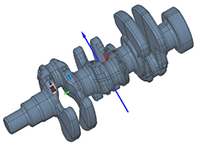

Products are made into appropriate forms for forging according to the predetermined basic structure. Product validation is also possible at this stage through a structural analysis program, which contributes to the improvement of product design accuracy.

![]()

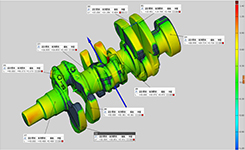

We employ a forging simulation system to effectively verify formability, yielding percentage, die life, and confirm the presence or absence of defects from a multifaceted perspective.

![]()

All dies undergo dimensional measurement to confirm their accuracy. We ensure not only the quality of forged products, but also their traceability.

Die

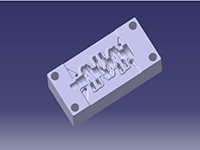

Die models designed with CAD

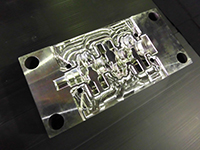

Dies that have undergone all manufacturing processes

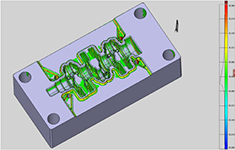

Indication of divergence between both products by color

3D scanner

![]()

Quality is improved by careful operation of each process. We perform visual checks to ensure quality.

![]()

Employing specialized computer software to overlay 3D scans of products enables quick comparison with design values. These results are effectively used for visual and quantitative evaluation to identify points for improvement to ensure highly precise products.

Product

CAD die models

Forged products

Indication of divergence between both products by color

3D scanner

Material testing is designed to measure the strength of ferrous and non-ferrous materials used in the manufacture of forged products.

The obtained data is used in CAE analysis and the evaluation of product strength.

Tensile strength

tester

Repeated bending

fatigue testing machine

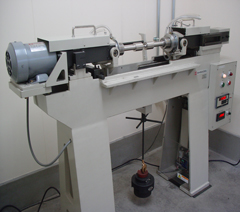

Rotary bending

fatigue testing machine

Charpy impact

tester

We have a wide range of testing machines equipped for incidental components such as fatigue and flexible and static strength.

We employ these to confirm that the products designed and manufactured by TFO satisfy the strength required by our customers.

Strength tester

Drop-weight impact tester

We measure the hardness of forged products to confirm that forging and heat treatment are successfully completed.

Hardness meter

Rockwell

Brinell

Vickers

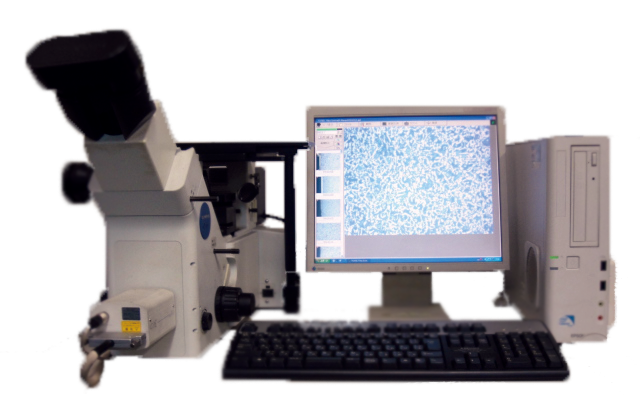

Forged product structure is observed at the micro and macro levels to confirm that forging and heat processing are successfully completed.

Metal structure observation equipment

Precision cutting equipment

Sample embedding equipment

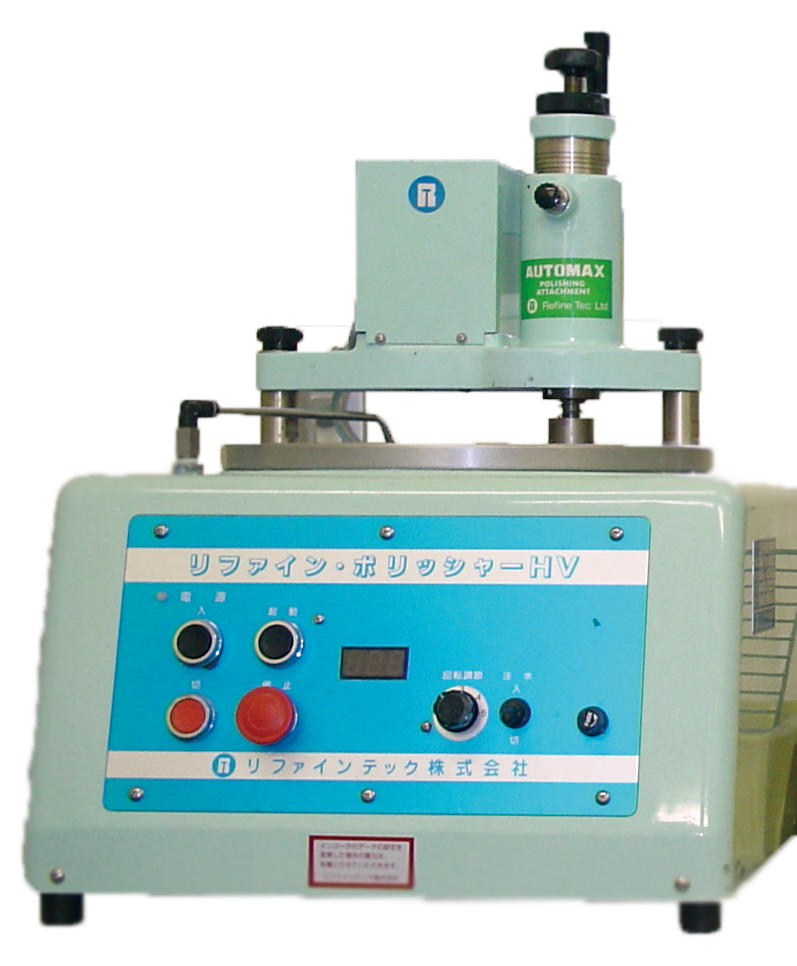

Sample polishing equipment

Metallurgical microscocpe

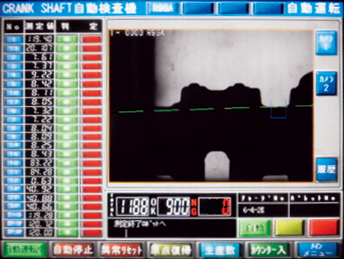

We implemented image measurement equipment for crank twisting to perform highly-accurate measurement for all products.

Also, we utilized accumulated product data to realize the maintenance of stable product quality.

Please use the below contact information for estimates and inquiries about our products.